Photovoltaic grid-connected cabinet is an important part of connecting string inverter and step-up transformer or AC junction box or step-up transformer. The incoming line of this photovoltaic grid-connected cabinet adopts circuit breaker input or direct input, the output adopts circuit breaker or load isolating switch, the busbar adopts electroplated or purified busbar connection, and provides secondary lightning protection. The rated voltage of the system is AC400v, the protection level is IP40 indoors and IP54 outdoors; the secondary measurement and control circuit, the current is greater than 2.5mm, the cable is greater than 1.5mm, the control is greater than 1.0mm, the measuring current transformer is 0.5-level current transformer, and the metering transformer is 0.2S-level current transformer. Related functions can also be added according to customer requirements. This product adopts professional electrical design and component selection to make the internal structure of the cabinet safe, simple, beautiful, convenient for on-site wiring and maintenance, and ensure long-term stable operation of the equipment.

Scope of application

Applicable to two types of photovoltaic power generation systems, village-level and large-scale industrial and commercial, to meet customized needs, working voltage AC400V, AC690V.

Can be fixed installation design or plug-in design:

Use well-known domestic and foreign brand circuit breakers and components to form functional units, with excellent technical performance, safe and reliable:

Can be composed of various standard unit modules for customers to assemble at will:

Use isolation between areas and mutual isolation between the incoming and outgoing lines of functional units to effectively enhance safety protection performance:

Combined assembly structure, all structural parts of the frame are firmly connected with screws, the frame, door and panel are electrostatically sprayed after phosphating, and all non-sprayed parts are galvanized and passivated.

It can meet the requirements of various components and can meet different working environments, and achieve the corresponding protection level:

The frame is made of high-quality steel plate, and the frame can be equipped with a 25m modulus

hole, which can be expanded for various purposes. There are two ways of entering the line: upper and lower side:

High breaking capacity, good dynamic thermal stability, flexible and practical electrical scheme combination, and the main parameters have reached the international advanced level.

| Model Specification | YHXL(PV Grid-connected Distribution Cabinet) |

| Quantity | 1 unit |

| Mains power access | Maximum Input Voltage | 400VAC 690VAC |

| Maximum Rated Current | 3150A |

| Phase Number | Three-phase four-wire + ground wire |

| Waveform | Sine wave (THD<3%) |

| Frequency | 50HZ |

| Switch Brand | As per user requirements |

| Inverter Connection | Voltage | Normal: Synchronized with mains power Supply Emergency: 380VAC ±3% |

| Waveform | Sine wave (THD<3%) |

| Frequency | Normal: Synchronized with mains power Supply Emergency: 50HZ ±0.5% |

| Input Circuit | One-way, two-way, four-way |

| Switch Brand | As per user requirements |

| Communication | RS232/RS485, Communication protocol: MOUDBUS or as per customer requirements |

| Electrical Clearance | ≥10mm |

| Creepage Distance | ≥12.5mm |

| Protection Class | IP54 |

| Rated Current of Main Busbar | 10A-400A |

| Rated Withstand Voltage | 8KV |

| Rated Short-Time Withstand Current | 10KA |

| Implementation Standard | GB/T7251.3-2017 |

| Measurement Data | Three-phase voltage / Three-phase current / Active power / Apparent power / Power factor / Frequency / Electricity |

| Working Environment | Noise (1m distance) | Noiseless |

| Temperature | 40-85% non-condensing, non-corrosive gas environment |

| Humidity | -20℃-40℃ |

| Enclosure Material | 201 stainless steel |

| Overall Size of Main Unit | Main unit dimensions: 800*600*2260 |

| Door Opening Method and Wiring Method | Front door single opening, bottom entry and exit (standard type) |

| According to Method | Floor-standing |

Photovoltaic grid-connected distribution box

Applicable to household and small industrial and commercial photovoltaic power generation systems to meet customized system customization needs.

Working voltage: AC230V, AC400V

| Model Specification | YHX/10-110KW (Distribution Box) |

| Utility Power Input | Voltage | 220V/380VAC ±20% |

| Phase Number | Single-phase/Three-phase four-wire + ground wire |

| Waveform | Sine wave (THD<3%) |

| Frequency | 50HZ ±10% |

| Switch Brand | According to user requirements |

| Inverter Input | Voltage | Normal: Synchronized with mains electricity Emergency: 380VAC ±3% |

| Waveform | Sine wave (THD<3%) |

| Frequency | Normal: Synchronized with mains electricity Emergency: 50HZ ±0.5% |

| Input Circuit | 1-way/2-way/3-way/4-way |

| Communication | RS232/RS485, Communication protocol: MOUDBUS or as per customer requirements |

| Protection Function |

| Short Circuit Protection | Yes |

| Overload Protection | Yes |

| Lightning Protection | Yes (Rated current: In: 20KA, Imax: 40KA, Up ≤4kW) |

| Isolation Protection | Yes (Knife switch/hand-operated isolating switch) |

| Over and Under Voltage Protection | Yes |

| Automatic Reclosing | Yes |

| Grid Connection Switch |

|

Photovoltaic Special Miniature Recloser Circuit Breaker (Optional)

20A~100A | 1. Automatic tripping when power grid failure or overvoltage > 20% (operating handle action); 2. Automatic closing when power grid returns to normal (operating handle action); 3. Manual operation and automatic operation can be switched; 4: Check voltage closing |

| Electrical Clearance | ≥3.0mm |

| Creepage Distance | ≥5.6mm |

| Protection Level | IP65 |

| Impact Protection Level | 1K10 |

| Rated Current of Main Busbar | 63A/100A/125A/160A/250A |

| Rated Short-Time Withstand Current | 6KA |

| Implementation Standard | GB/T7251.3-2017 |

| Working Environment | Noise (1m Distance) | Noiseless |

| Temperature | Operating temperature: -25 to +60°C Storage temperature: -40 to +70°C |

| Humidity | Humidity: 0-90% without condensation; no corrosive gas environment (if any, please specify) |

| Operating Altitude | ≤300OM |

| Salt Spray Resistance | Standard salt spray test for 336 hours |

| Enclosure Material | PC/Stainless steel/Cold rolled steel/Glass fiber reinforced plastic (SMC) (optional) |

| Installation Method | Wall-mounted |

| Overall Dimensions of Main Unit | Customized |

| Door Opening Method and Wiring Method | Front door single opening, bottom entry and exit (standard type) |

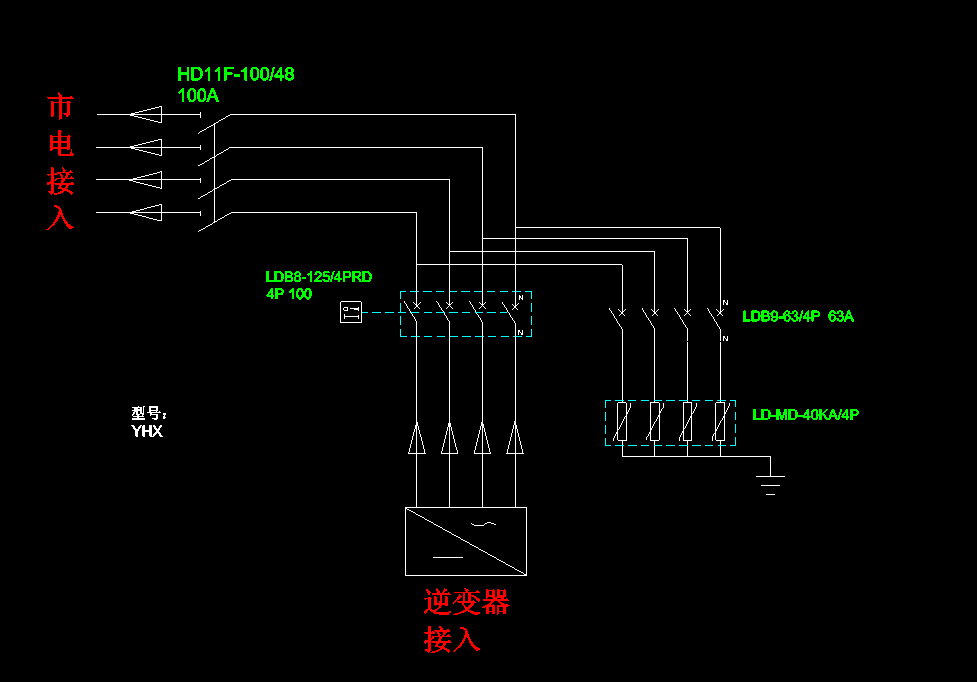

Working principle diagram of YH photovoltaic grid-connected series distribution box and distribution cabinet

Wall-mounted installation, embedded concealed installation, surface installation, floor installation (customizable)

Photovoltaic grid-connected distribution boxes and distribution cabinets, distribution boards, distribution screens, etc. are complete sets of equipment for centralized installation of switch integrated distribution box wiring guidance, instruments and other equipment.

A variety of self-resetting over- and under-voltage protectors and photovoltaic special reclosing circuit breakers are available to meet the use needs and acceptance standards of different regions; the box cover requires a professional key to open, realizing professional management;

Plastic spray box and stainless steel box are optional; outdoor installation, safer to use; support special requirements and function customization.

The metal distribution box has a higher protection level, and the commonly used protection levels are: IP30, IP44, IP54, IP55, IP65, explosion-proof.

Reasonable distribution of electrical energy, convenient for the opening and closing operation of the circuit.

It has a higher safety protection level and can intuitively display the conduction status of the circuit.

It is easy to manage and is conducive to maintenance when a circuit failure occurs.

Photovoltaic grid-connected distribution box is a low-voltage distribution device that assembles switchgear, measuring instruments, protective electrical appliances and auxiliary equipment in a closed or semi-closed metal cabinet or on a screen according to electrical wiring requirements. In normal operation, the circuit can be connected or disconnected with the help of manual or automatic switches. In case of failure or abnormal operation, the circuit can be cut off or an alarm can be given with the help of protective electrical appliances. Various parameters in operation can be displayed with the help of measuring instruments, and some electrical parameters can also be adjusted, and prompts or signals can be issued for deviations from normal working conditions. It is often used in various power generation, distribution and substations.